-

Rounded corner processing: Quickly trims sharp corners of paper or cards into rounded corners, preventing hand injuries.

-

Wide material compatibility: Suitable not only for paper but also for PVC, plastic sheets, and more.

-

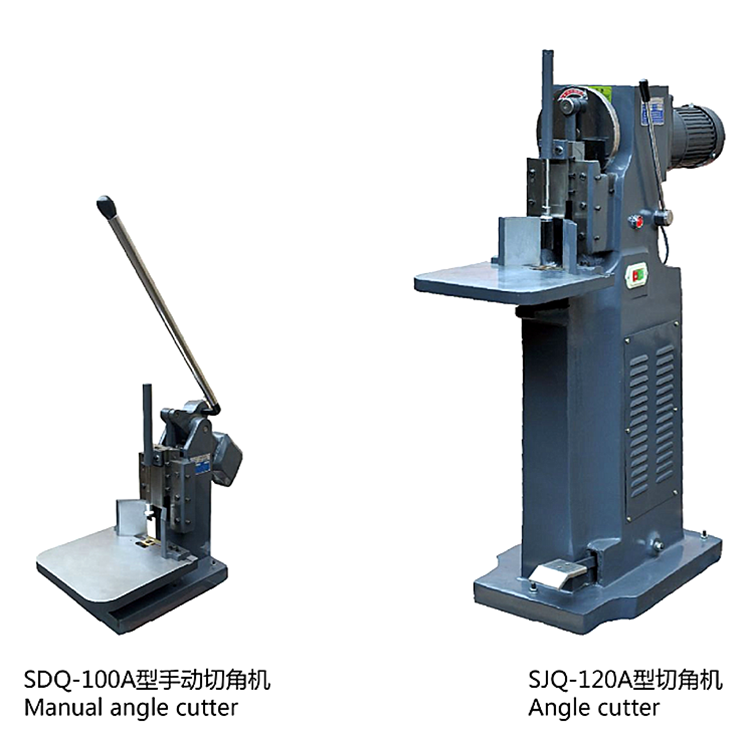

Easy operation: Manual corner cutters are lightweight and user-friendly, while electric models offer higher efficiency.

-

Precise cutting: Sharp dies ensure clean, consistent, and uniform rounded corners.

-

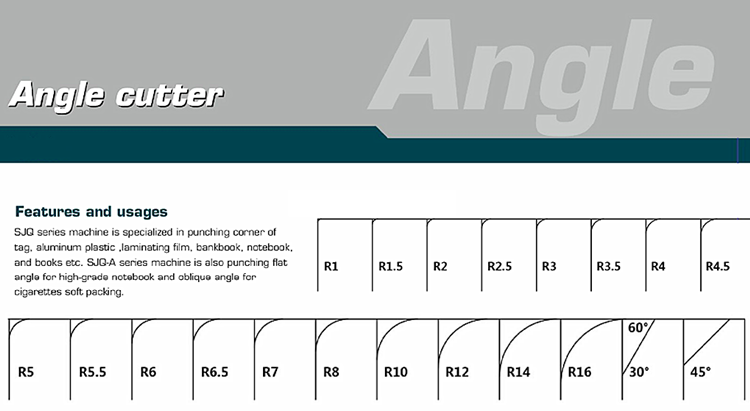

Multiple specifications available: Common corner radii include R3, R5, R8, etc., which can be selected flexibly based on different needs.

2. Application Areas of Corner Cutting Machines

-

Printing industry: Rounding corners of business cards, brochures, posters, and tags to enhance overall aesthetics.

-

ID and card production: Cutting rounded corners for PVC cards such as ID cards, membership cards, and employee badges.

-

Office and stationery: Rounding corners of documents and folder covers to prevent wear and tear during use.

-

Packaging processing: Cutting rounded corners on gift boxes, labels, and packaging to give products a more premium look.

3. How to Choose a Corner Cutting Machine

-

Choose based on production volume:

-

Small batches → Manual corner cutting machines, cost-effective.

-

Large batches → electric corner cutter or hydraulic corner cutting machines, more efficient.

-

-

Pay attention to die specifications: Check whether common corner radii are available and if die replacement is convenient.

-

Consider material and thickness: Ensure the machine can cut the required materials, such as PVC, coated paper, or plastic sheets.

-

After-sales service and consumables: A reputable manufacturer can provide long-term die supply and reliable after-sales support.

4. Why Choose a Professional Corner Cutting Machine Manufacturer?

Selecting an experienced manufacturer ensures the precision and durability of the machine. High-quality suppliers offer multiple models (rounded corner machine, heavy duty corner cutter, visiting card round corner cutting machine) and can provide customization based on customer requirements.

Conclusion

As an important post-press processing device, corner cutting machines are widely used in printing, packaging, office work, and more. Choosing an efficient and durable corner cutting machine not only improves work efficiency but also significantly enhances product quality.

If you are looking for a cost-effective corner cutting machine, feel free to contact us for detailed solutions and quotations!