COMPANY NEWS

What are the benefits of using an angle cutter for post-printing?

A corner cutting machine is a widely used piece of equipment in the post-printing and manufacturing industry. It is employed to create different angles on products such as books, business cards, notebooks, and labels. In this article, we will explore the advantages of using a corner cutting machine and highlight the distinctive features of JCTPRINT's corner cutting machine.

Benefits of Using a Corner Cutting Machine

-

Enhanced Production Efficiency: The use of a corner cutting machine significantly boosts production efficiency. Compared to manual corner cutting, these machines can complete the task faster and with greater precision, saving time and human resources. This is especially beneficial for large-scale production and busy printing and packaging operations.

-

Consistency and Precision: A corner cutting machine ensures consistent and highly accurate angles. This is crucial for products that require a high-quality, uniform appearance, such as business cards and book covers. Consistent angles and dimensions improve the overall look and professionalism of the final product.

-

Cost Savings in Labor: Utilizing a corner cutting machine reduces the need for manual labor, ultimately lowering labor costs. The user-friendly design of corner cutting machines requires minimal supervision and setup, eliminating the need for complex manual operations.

-

Versatility Across Various Materials: Corner cutting machines are typically capable of processing a variety of materials, including paper, leather, PVC, hang tags, playing cards, and more. This versatility makes them an ideal choice for post-printing processing.

Unique Features of JCTPRINT's Corner Cutting Machine

JCTPRINT's corner cutting machine stands out in the market due to several distinctive features:

-

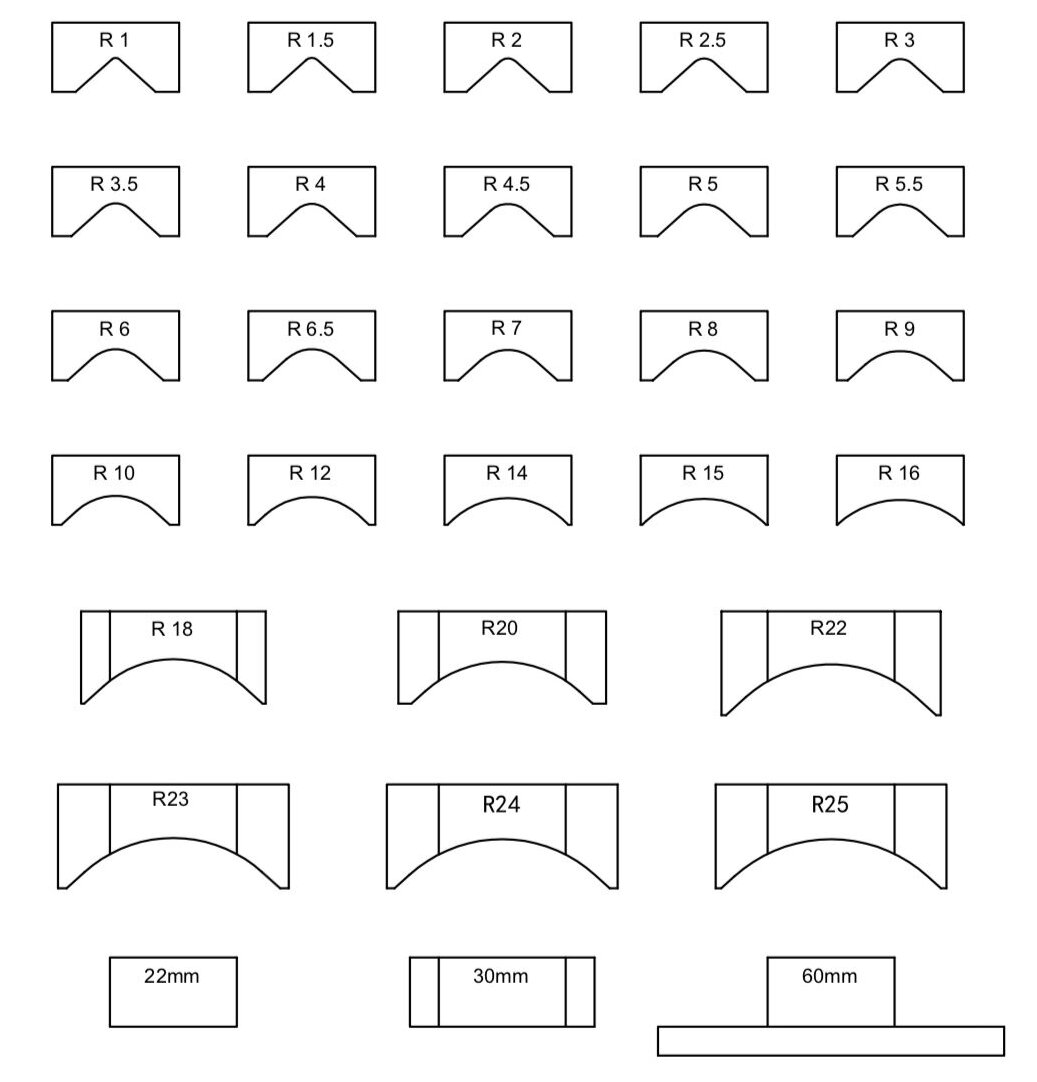

Multiple Optional Blade Specifications: JCTPRINT's corner cutting machine offers a range of optional blade specifications, from R2 to R12. This flexibility allows users to select the blade size that best suits their specific requirements, ensuring that the cut angles align with their design preferences.

-

Foot Pedal Operation: This machine is equipped with a foot pedal switch, making the operation more convenient, efficient, and safe. Operators can easily control the cutting head's movement with minimal effort.

-

Clutch Control: JCTPRINT's corner cutting machine features a clutch control system, providing enhanced cutting force that is hard to match with other models. This means it can handle materials of varying thickness and hardness without compromising the cutting quality.

-

Safety Protection Mechanisms: The machine incorporates multiple safety features, including automatic power cutoff when the machine cover is open and a dedicated blade adjustment safety button, ensuring the operator's safety.

-

Wide Range of Applications: JCTPRINT's corner cutting machine can be used for cutting a wide range of printed materials, including notebooks, labels, books, business cards, and playing cards. It has become an indispensable piece of equipment for post-printing processing.

In summary, a corner cutting machine is a vital piece of equipment in the post-printing industry, offering improved efficiency, cost savings in labor, and product quality assurance. JCTPRINT's corner cutting machine, with its various blade options, foot pedal operation, clutch control, and safety features, provides an efficient, secure, and reliable corner cutting solution suitable for the production and processing of various printed materials.

corner rounding machine

corner cutting machine

electric round corner cutter

electric corner rounder

paper round corner cutter