COMPANY NEWS

Anilox Roller Maintenance-Ultrasonic Cleaning

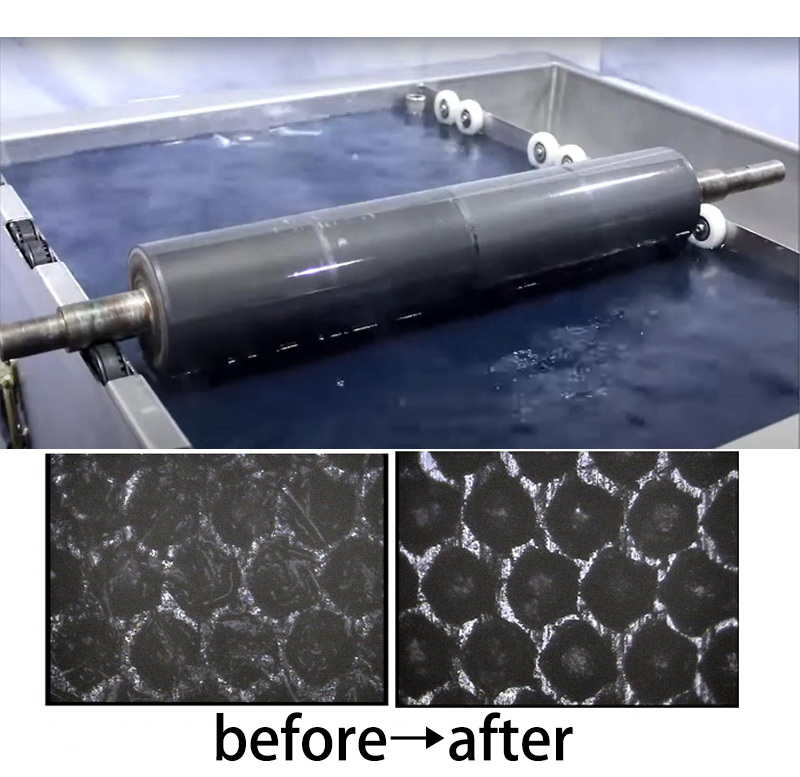

Ultrasonic Cleaning

Principle: Ultrasonic cleaning utilizes ultrasonic waves to create a phenomenon called cavitation, where tiny bubbles are mechanically formed. These bubbles implode when subjected to pressure and release energy that generates an agitating or dislodging effect, effectively removing ink residues and impurities from the mesh cavities of printing rollers.

Several factors influence the intensity of ultrasonic cavitation:

- Ultrasonic intensity: It is advisable to adhere to the recommended ultrasonic intensity standards provided by the cleaning equipment manufacturer.

- Ultrasonic frequency: Ultrasonic frequency is inversely proportional to cavitation intensity. Higher frequencies result in smaller bubbles and reduced cavitation strength. Typically, a frequency of 40,000 Hz is suitable for creating the required bubbles.

- Immersion temperature: Maintaining a solution temperature between 60°C to 70°C is ideal.

- Cleaning time: The cleaning duration is a crucial factor, as prolonged exposure to ultrasonic waves can damage the mesh cavities. Many ultrasonic cleaning methods incorporate a pre-soaking step followed by a 5-minute ultrasonic cleaning or a slightly shorter time to protect the mesh cavities.

Suitability: Ultrasonic cleaning is well-suited for addressing cases of inorganic dust blockages.

Setting adjustments: It is essential to consider the power and related settings of the ultrasonic cleaning machine, as different brands may have distinct cleaning configurations. Adjust the frequency to the optimal level, while ensuring that all settings are consistent, allowing for continuous cleaning and record-keeping of the printing rollers.

Using appropriate ultrasonic intensity, frequency, time, and solution temperature helps prevent excessive cleaning that could harm the ceramic mesh rollers.

Standardized cleaning: Ultrasonic cleaning should follow standardized procedures. Unlike other cleaning methods, ultrasonic cleaning is adjustable. If the desired cleaning results are not achieved or are not evident, operators may naturally increase cleaning power or extend cleaning time, potentially causing issues such as damage to the mesh cavities, scoring, or bulging.

Duration: Ceramic hardness varies, and the mesh cavities are, in fact, quite fragile. Cleaning time should not be excessively long. It is advisable to follow the 'more soaking, less vibrating' principle, which involves soaking for 10-20 hours and then vibrating for 10-30 minutes. Some users, unfamiliar with the principles of ultrasonic cleaning, may turn on the vibration as soon as they place the roller into the ultrasonic cleaning machine, leaving it vibrating continuously for hours or even more. This overuse of ultrasonic cleaning can damage the mesh cavities, leading to the formation of 'hickies' or ink spots on printed materials.

Combined cleaning: For stubborn substances, it is recommended to apply mesh roller cleaning agents before using ultrasonic cleaning. This can enhance the effectiveness of ultrasonic cleaning. Most printing plants that use ultrasonic cleaning also employ highly corrosive solutions to increase efficiency and reduce cleaning time. As flexographic printing primarily uses water-based inks, the ultrasonic cleaning method includes a pre-soaking process to soften residual ink and other hard impurities inside the ceramic mesh rollers, with the duration ranging from 0.5 to 24 hours.

Advantages:

- No manual intervention required.

- Effective for stubborn blockages.

Disadvantages:

- Expensive equipment, requiring additional cleaning solvents.

- Precise control of ultrasonic parameters is crucial. Incorrect assessment of the mesh roller blockage may result in damage. Overusing ultrasonic cleaning may weaken the mesh cavities, leading to issues like vertical dark bands and dot gain.

- Regular low-frequency use is necessary, but frequent use can damage the mesh cavities, affecting roller lifespan.

Caution: For sleeve-type mesh rollers or aluminum-based mesh rollers, it is advisable to avoid using ultrasonic cleaning as prolonged exposure to cleaning solutions can damage their structures and bonding between ceramic and roller base, leading to ceramic detachment and shortened roller lifespan.

Avoid excessive frequency: Prolonged vibration causes microcracks on the ceramic mesh roller surface. These cracks accumulate and allow high pH or aggressive chemicals to penetrate the porous ceramic coating, resulting in corrosion that affects the roller's lifespan.